🛡️ Free 1-Year Warranty.No matter what, every product comes with a 1-year free warranty to give you peace of mind!🔥🔥Our goods are authentic, with genuine patents, counterfeit must be investigated! Customers please identify our products!

✅Guaranteed! GoogleTrusted Store!✅🏪PalPay certified reputable merchant.💵Has paid 100k USD in PayPal as store guarantee

✨If you are not satisfied within 30 days, you can return it for free.

💳Fast refund >> 100% guaranteed refund.

🔥Handling time>> Ship within 24 hours after payment.

✈Shipping to Ghana mainland, free delivery, same price🕒 Delivery within 2–7 days across Ghana.

💛💚Special Event Today: We'll randomly select 3 lucky customers to receive double the items on their order. We'll notify you via email, so please check your inbox! Thank you!💜🧡

![]()

We're celebrating 90 years of Festool with a special anniversary offer.

![]()

![]()

![]()

![]()

We have an excellent customer service team who are very happy with all our customers, both new and old.

![]()

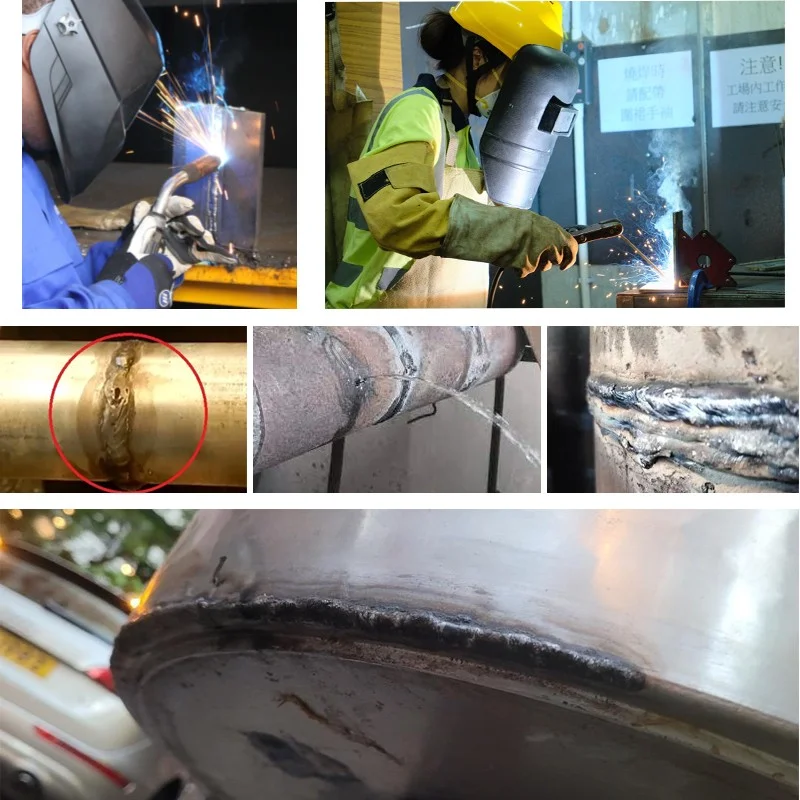

Most stainless steel products are manufactured using traditional welding processes such as TIG welding.

Z. Although this method can meet 80% of production requirements, it will result in welded products.

Insufficient weld penetration and defects such as air pockets, bubbles and cracks. These defects not only reduce the strength of the joint. They can also cause corrosion of the welds.

![]()

The welding process requires more than just an experienced welder. But the material costs are also high. This increases production costs, and the finishing after welding is very slow.

![]()

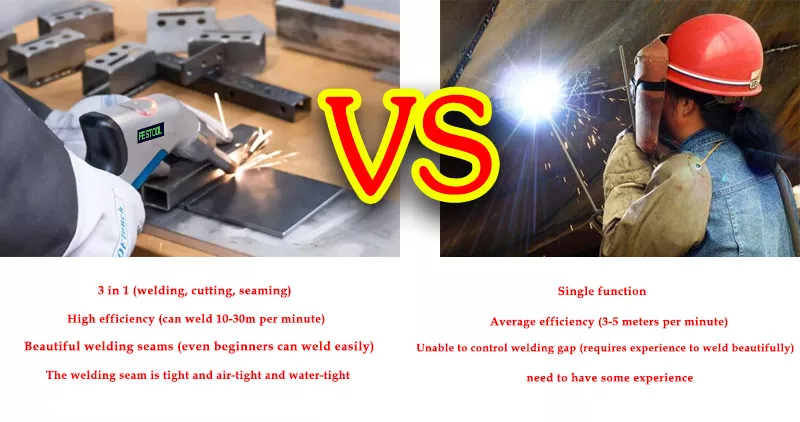

It not only solves the problems of traditional welding, but also improves the waterproof performance under water and in rainy days. (Greatly avoids the problem of being unable to work in rainy days and greatly improves work efficiency)

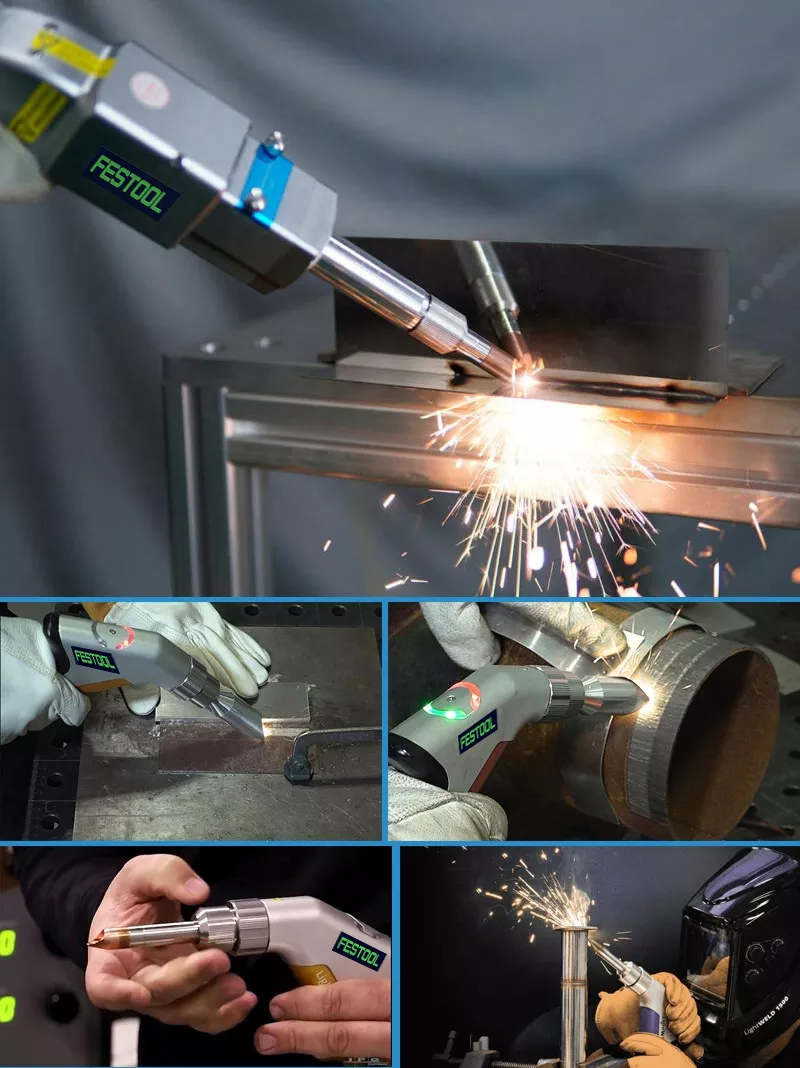

Because this product is an upgraded version of the portable laser welding machine. It adds new functions (rust removal).

This creates a new type of welding, the advantage of which is ease of operation. The welding pattern is beautiful, the welding speed is fast, and the material is saved.

![]()

The portable laser welding machine offers high welding speeds, 2 to 10 times faster than traditional welding methods, saving at least two welders per year.

![]()

It can be used not only for cooking, but also for cutting various materials (gold / silver / copper / iron / aluminum / stainless steel / galvanized sheet, etc.). Cutting thickness 0-25 mm.

Welding, cutting and deoxidation work.

![]()

Product demonstration

![]()

😊If you are not satisfied with the goods you received, please contact us within 30 days of receipt, we will give you the best help!

🚢 Shipping;🌍We ship worldwide, no matter where you are 🌍Estimated delivery time = production time (1 day) + delivery time 🌍Express shipping: 4-7 days 🌍Standard shipping: 5-10 days🚚Risk-Free Shipping: If your order doesn’t arrive within 60 days, you will receive a full refund.

💐 WHY SHOP WITH US?

🏭 Direct from Manufacturers:

We work closely with trusted suppliers worldwide to bring you high-quality products at fair prices.

🧾 Strict Quality Control:

Every item is inspected before shipping to ensure it meets our standards.

💰 Affordable Prices, Genuine Products:

No middlemen. No inflated costs. Just real value.

💬 Responsive Customer Support:

Our team is always ready to help you with any questions or order updates.

⭐ Loved by Customers Across Ghana:

Thousands of happy buyers have rated our products for quality, reliability, and service

100% Satisfaction Guaranteed With Every Order.